Thông tin chi tiết sản phẩm:

Thanh toán:

|

| Laser power: | 400W ( other power can be optional ) | Max. speed of the table: | 100mm/s |

|---|---|---|---|

| Positioning accuracy: | 0.05mm | Repeat positioning accuracy: | 0.02mm |

| Cooling: | Water cooling | Pulse width: | 0.1~50.0ms |

| Power supply requirement: | 380V±10%,50Hz,40A | Electricity requirement: | 12-15kW,three phase |

| Power feedback loop: | Energy feedback system | Robot brand: | ABB ( can choose other brand ) |

| Robot arm length: | 1400mm ( can choose other arm length ) | ||

| Điểm nổi bật: | laser welding machine for stainless steel,laser welding system |

||

400W Laser Welding Machine For Cooker Hood , 3D Automatic Laser Welder

1, Machine main features

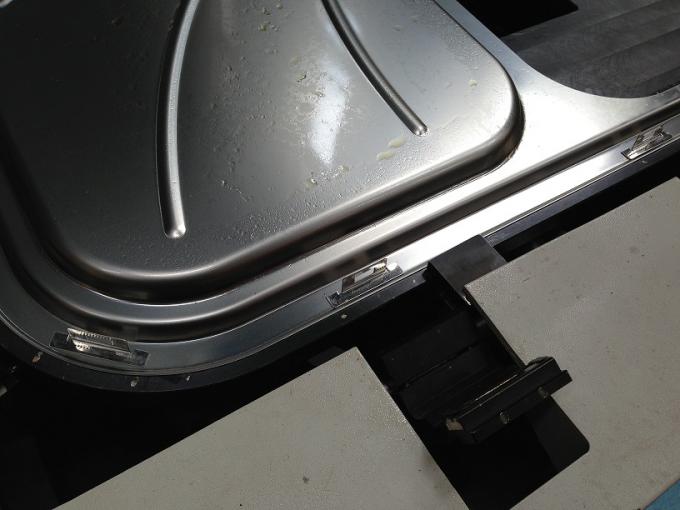

1.1. This kitchen sink laser welding machine designed special for different kinds of sinks, special for big stainless steel kitchen products which need the automatic dot welding, like the kitchen sink, the cooker hood, gas cooker etc, machine match the ABB industrial robot to achieve the automatic laser dot welding.

1.2. Machine optic system use the fiber transmission instead of the mirrors reflect which has low future failure rate and high electro-optic conversation.

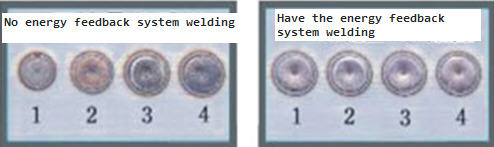

1.3. Industry-leading "energy negative feedback" will shock optical output power fluctuation control in less than 3%, to ensure that the laser stable power output, thereby improving welding stability, the advantages of the energy feedback, pls check the below comparations:

1.4. Machine with energy feedbback system which can improve the sink welding quality, on the surface of the sink no versible mark and no welding trace.

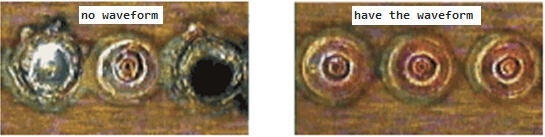

1.5. Our sink fiber laser welding machine has the waveform control system, so it can ensure the each laser dot output is very stable and uniform, the below is the comparation between machine have the waveform control and without waveform control :

1.6. Machine can be worked with the special fixtures.

2, Machine's application fields

Our sink fiber laser welding machine is widely used in the kitchen sinks industrial, bathroom industrial and stainless steel sink industrial, vacuum ,cup, bowl, the door - handle and the spark plugs, filter, grease, a heating tube, support the cooker hood laser welding industrial etc.

3, Machine's application materials

The 304 and 316 stailnless steel, plain carbon steel, alloy steel,iron, stainless steel, low carbon steel, steel -310 316 stainless steel, alloy steel and 347 nickel, different levels of nickel, titanium, nickel, tin, copper, aluminium, niobium, gold, silver of metal or alloy the same metal for the welding. copper and nickel, titanium, copper and nickel, titanium, titanium, molybdenum, brass, copper, and low carbon steel, copper, metal for the welding.

4, Machine main technical parameters

|

Model |

ST-P400-R |

|

Wavelength |

1064nm |

|

Pump sources |

Two Xe-lamp (imported), Gold plating chamber |

|

Max.power |

400W |

|

Max. single pulse energy |

80J |

|

Pulse width |

0.1~50.0ms |

|

Sequency frequency |

1~200Hz |

|

Welding spot size |

0.2~1.5mm |

|

Welding depth |

0.1~3.0mm |

|

Sequence welding |

15mm/s |

|

Observe system |

CCD monitor |

|

Positioning |

Red light indication |

|

Cooling system |

Water cooling |

|

Repeatability precision |

0.02-0.05mm |

|

Machine host size |

770mm*1350mm*1200mm (L*W*H) |

|

Water chiller size |

600 * 880 *1450 mm |

|

Electricity requirement |

12-15kW,three phase |

|

Power supply requirement |

380V±10%,50Hz,40A |

|

Machine total Gross weight (KG) |

800KG |

5, The medical instrument laser welding samples photos