Thông tin chi tiết sản phẩm:

Thanh toán:

|

| Laser power: | 300W ( other power can be optional ) | Max. speed of the table: | 100mm/s |

|---|---|---|---|

| Z axis adjustment: | Manually or serov motor linkage CCD monitoring system | Positioning accuracy: | 0.05mm |

| Repeat positioning accuracy: | 0.02mm | Cooling: | Water cooling |

| Pulse width: | 0.1~50.0ms | Power supply requirement: | 380V±10%,50Hz,40A |

| Electricity requirement: | 12-15kW,three phase | Power feedback loop: | Current feedback system |

| Điểm nổi bật: | laser welding system,fiber welding machine |

||

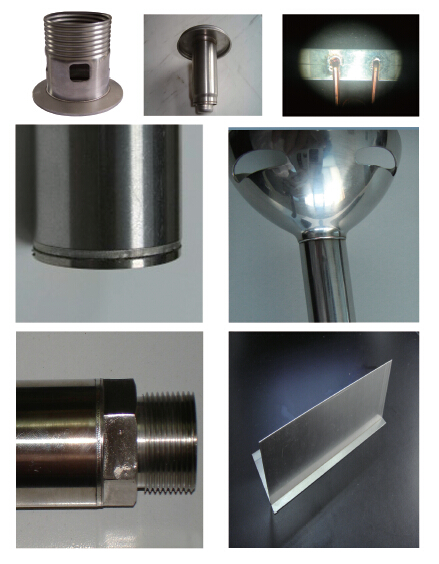

300W laser welding euipment for pipe welding , with 5 axis linkage , automatic welding

1, Machine main features

1.1. With automatic translation table to fulfill large format spot welding, implementing online spot welding, fast speed, flexible processing.

1.2. Machine optic system use the fiber transmission instead of the mirrors reflect which has low future failure rate and high electro-optic conversation.

1.3. Cooperating with the relevant fixtures, within the scope of the 2-3 axis working table which can realize automatic welding.

1.4. Capable of carrying multi-axis linkage control system, realize the complex graphics continuous automatic welding.

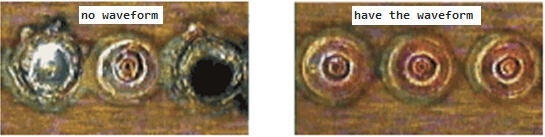

1.5. Our fiber laser welding machine has the waveform control, it can ensure the every laser dot output with same laser power and very uniform, the below two photos are the welding compare between the machine with and without the waveform control :

2, Machine's application fields

Our fiber laser welding machine is widely used in the pipe welding industrial, advertisement industry, glass frame welding, stainless steel frame welding, the keyboard welding, silicon steel welding and stainless steel at welding, furniture and vacuum ,cup, bowl, the door - handle and the spark plugs, filter, grease, a heating tube, support metal tube etc.

3, Machine's application materials

The stailnless steel, plain carbon steel, alloy steel,iron, stainless steel, low carbon steel, steel -310 316 stainless steel, alloy steel and 347 nickel, different levels of nickel, titanium, nickel, tin, copper, aluminium, niobium, gold, silver of metal or alloy the same metal for the welding. copper and nickel, titanium, copper and nickel, titanium, titanium, molybdenum, brass, copper, and low carbon steel, copper, metal for the welding.

4, Machine main technical parameters

|

Model |

ST-A150 |

ST-A300 |

ST-A400 |

ST-A500 |

|

Max. laser power |

150W |

300W |

400W |

500W |

|

Laser working medium |

Nd: YAG |

|||

|

Laser wavelength |

1064nm |

|||

|

Max. output current |

≤300A |

|||

|

Single pulse Max. laser power |

45J/10ms |

60J/10ms |

90J/10ms |

100J/10ms |

|

Memory waveform |

32 Groups |

|||

|

The energy stability |

±4% |

|||

|

Uniformity of energy distribution |

±3% |

|||

|

Laser beam split mode |

Time splitting or energy split or instantaneous light |

|||

|

Max. laser beam splitting number |

4 routes |

|||

|

Laser energy control method |

Current minus feedback |

|||

|

Single pulse width |

0.1-50ms |

|||

|

Pulse frequency |

1-300HZ |

|||

|

Targeting and positioning |

Red light ( the CCD is optional ) |

|||

|

Machine total power consumption |

6KW |

12KW |

14KW |

15KW |

|

Cooling method |

Water cooling |

|||

|

Power supply requirement |

3 phase, 380V/50HZ |

|||

|

Machine host ( laser Generator ) size |

720mm(W)*1500mm(L)*1400mm(H) |

|||

|

Water chiller size |

950 * 650 * 1500mm ( L * W * H ) |

|||

5, The laser welding samples photo